Photoluminescent Pigment for Plastic Moulding and Fiber Drawing

Product Description:

Our photoluminescent pigment can be well dispersed in PS, PP, PE, ABS, PVC, PMMA and other plastic. It is suitable for injection moulding and drawing fibers.The plastic product made with our glow in the dark powder can glow for 12 hours. It is strontium aluminate glow in the dark powder with a day color of light yellow and a glow color of yellow green. It is non-radioactive, non-toxic,very weatherproof, very chemically stable and with a long shelf life of 15 years.

Application:

It can be well dispersed in PS, PP, PE, ABS, PVC, PMMA and other transparent plastic. It is suitable for application like drawing fiber and injection moulding.

Specification:

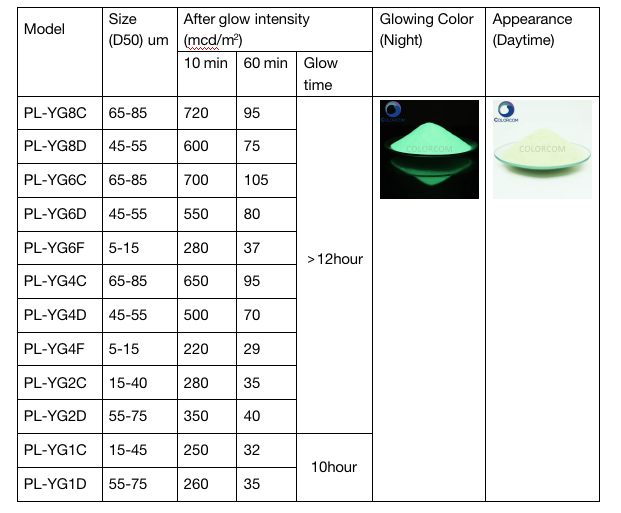

PL-YG Photoluminescent Pigment for Plastic Moulding and Fiber Drawing:

For plastic moulding, we recommend photoluminescent pigment with grain size class C or D.

For fiber drawings, we recommend photoluminescent pigmet with grain size F.

Note:

★ Luminance test conditions: D65 standard light source at 1000LX luminous flux density for 10min of excitation.

★ We do not recommend clients to use glow in the dark powder directly to make the final plastic products because it can easily turn black during the heating process, which will reduce the brightness of plastic and affect the product's appearnce. It is better to use photoluminescent pigment to make glow in the dark masterbatch first, and then use the masterbatch for further processing.