Fluorescent Brightener VBL | 12224-06-5

Product Description

Fluorescent Brightener VBL is a bis-triazine amino type fluorescent brightener with a blue-violet fluorescent colour. It is soluble in 80 times softer water, resistant to acid and alkaline pH 6-11, dye bath pH 8-9, with increasing acidity the fluorescence gradually decreases. Resistant to hard water up to 300ppm, free chlorine up to 0.25%, not resistant to high temperature baking, not resistant to copper, iron and other metal ions. Can be used with anionic surfactants, non-ionic surfactants and hydrogen peroxide, but not with cationic surfactants, cationic dyes and synthetic resins.

Applicable industries

For whitening of white products in cotton and viscose, and for brightening of light coloured or printed products.

Other Names: Fluorescent Whitening Agent, Optical Brightening Agent, Optical Brightener, Fluorescent Brightener, Fluorescent Brightening Agent.

Product Details

|

C.I. |

85 |

|

CAS NO. |

12224-06-5 |

|

Molecular Formula |

C36H34N12Na2O8S2 |

|

Content |

≥ 99 % |

|

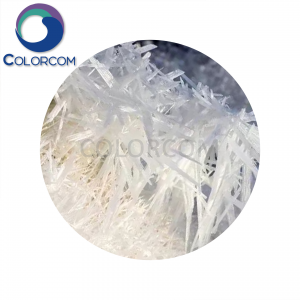

Appearance |

Light yellow powder |

|

Fluorescent Intensity |

100 |

|

Water-insoluble Matter |

≤ 0.5% |

|

Moisture |

≤ 5.0% |

|

Application |

Suitable for whitening and brightening of cotton and viscose, with average lightfastness. Good affinity for cellulose fibres, average evenness. Suitable for printing and dyeing, rolling and dyeing, printing pulp. Also used for brightening and colouring of vinylon, nylon, pulp and paint. |

Performance characteristics

1. Anionic, can be used in the same bath as anionic surfactants or dyes, non-ionic surfactants and hydrogen peroxide.

2. Not suitable for use in the same bath with cationic surfactants or dyestuffs.

3. Fluorescent Brightener VBL is stable to insurance powder.

4. Fluorescent Brightener VBL is not resistant to copper, iron and other metal ions.

Method of Application

1.For printing and dyeing, dosage: 0.08-0.3%, bath ratio: 1:40, best dyeing bath temperature: 60℃, PH 7-9, dyeing time 20-30 minutes.

2.For paper making, dissolve in 80 times water and add to pulp and paint, the dosage is 0.1-0.3% of the dried pulp or dried paint.

Storage and Notes

1.It is recommended that Fluorescent Brightener VBL be stored in a cool, dry place away from light for a storage period of 2 years.

2.Fluorescent Brightener VBL is allowed to crystallize a little after 2 months of storage, which will not affect the use effect during the shelf life.

3.Fluorescent Brightener VBL can be mixed with anionic and non-ionic surfactants, direct, acidic and other anionic dyes and paints, but should not be used in the same bath with cationic dyes and surfactants, synthetic resin primers.

4.The water quality used should preferably be soft water and should not contain copper, iron and other metal ions or free chlorine.

5.The amount of fluorescent brightener VBL should be appropriate, in case of excess, the whiteness will be reduced or even yellowed.

Product Advantage

1.Stable Quality

All products have reached national standards, product purity of more than 99%, high stability, good weatherability, migration resistance.

2.Factory Direct Supply

Plastic State has 2 production bases, which can guarantee the stable supply of products, factory direct sales.

3.Export Quality

Based on domestic and global, the products are exported to more than 50 countries and regions in Germany, France, Russia, Egypt, Argentina and Japan.

4.After-sales Services

24-hour online service, the technical engineer handles the whole process regardless of any problems during the use of the product.

Packaging

In 25kg drums (cardboard drums), lined with plastic bags or according to customer’s requirements.